Environmental Protection

Air Pollution Control

The Company complies with the ISO 14001 environmental management system and continues improvement of its production operation, products and services to reduce the impact on the natural environment. Tung Ho Steel continues to monitor and is devoted to air pollution prevention and control. By adopting the best available control technology (BACT), the emission of particulate pollutants is effectively reduced.

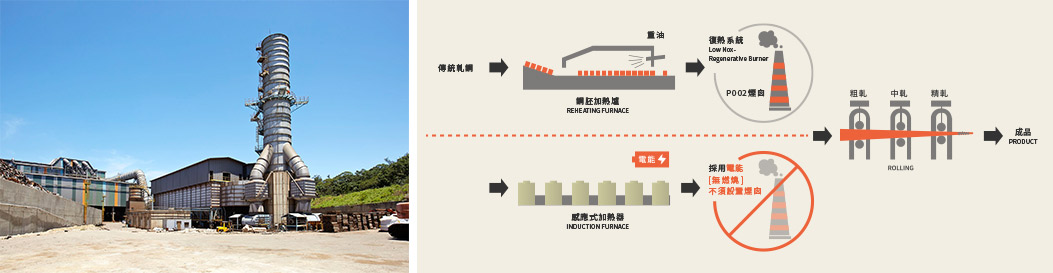

The production process in Taoyuan Works adopts the direct rolling method without a heating furnace, which is more environmentally friendly compared with the traditional use of fuel oil for heating. The steel rolling production lines in Miaoli Works and Kaohsiung Works-Jiaxing mainly use natural gas to heat the steel billets, and advanced combustion equipment is adopted to reduce pollutant emissions. Natural gas is used to replace low-sulfur fuel in part of the process to greatly reduce the emissions of CO2 (carbon dioxide), NOx (nitrogen oxide), and SOx (sulfur oxide). In 2024, the transformation of the fuel equipment at Kaohsiung works-Jiaxing was completed and we selected low-carbon natural gas to reduce pollutant emissions. All works comply with the air pollutant emission standards, and the average monitoring value of emissions in 2024 was in line with the local air pollutant standards.

Water Pollution Control

All the Works have relevant wastewater treatment procedures and application for discharge permit in place in accordance with the water pollution control regulations. The wastewater (sewage) from the main production plants is reclaimed and reused after passing through appropriate wastewater treatment facilities. Part of the reclaimed water is used for watering the green space in the Works and suppressing dust.

In 2020, Taoyuan Works applied for changes in water measures and canceled wastewater discharge to achieve zero wastewater discharge. Miaoli Works discharges wastewater to Xihu River (the average daily discharge is 246m3/day, lower than the approved daily discharge of 950 m3/day) through the water meter. The runoff wastewater(rainwater) from Kaohsiung Works-Jiaxing is discharged into Yamshuigang Stream, and the wastewater from the manufacturing process in Kaohsiung Works-Jiaxing and Kaohsiung Works-Daye is included into the Kaohsiung Linhai Linyuan & Dafa Industrial Parks Combined Wastewater Treatment Plant and discharged into the adjacent waters (Taiwan Strait), with the daily maximum discharge volume of 525 tons. The joint sewage treatment plant will inspect the quality of the discharged water in the plant area from time to time. The water volume is declared and discharged in accordance with regulations, and the treatment fees are paid every month as required. Wastewater in the Head Office belongs to general domestic wastewater, which is discharged into public sewage sewers and is collected into Taipei City Sewage Treatment Plant for treatment.

Waste Treatment and Recycling

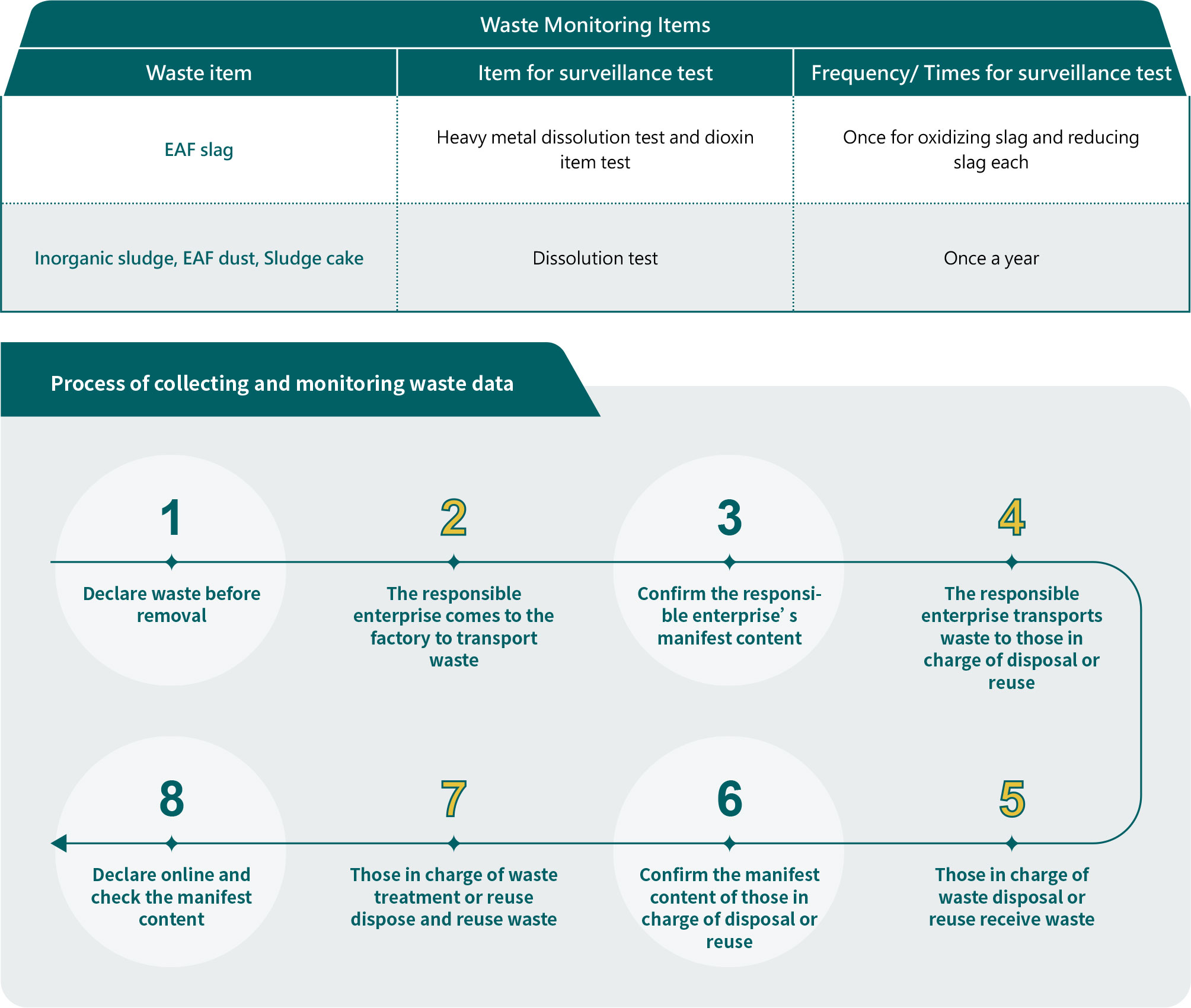

Various waste in our all Works is placed by classification. Before outsourcing the removal and treatment of waste in the plant to qualified vendors in accordance with the method approved by the Waste Disposal Plan, it is necessary to confirm that the entrusted treatment company has the required qualifications and capabilities, and the permit for removal and treatment operations issued by the competent authority. In addition, the generation of waste, storage, removal and disposal of industrial waste should be declared online before the entrustment contract is signed. The declared information should be kept for three years. In addition to designating people to control the waste generation, the management of waste storage, removal, treatment and reuse of the entrustee will also be inspected and records are also kept for future reference.

In addition, all works of the Company have established an autonomous waste inspection and audit system, and the results are all kept in written records. Improvement of defects is also followed up and included in the main point of autonomous inspection and audit.

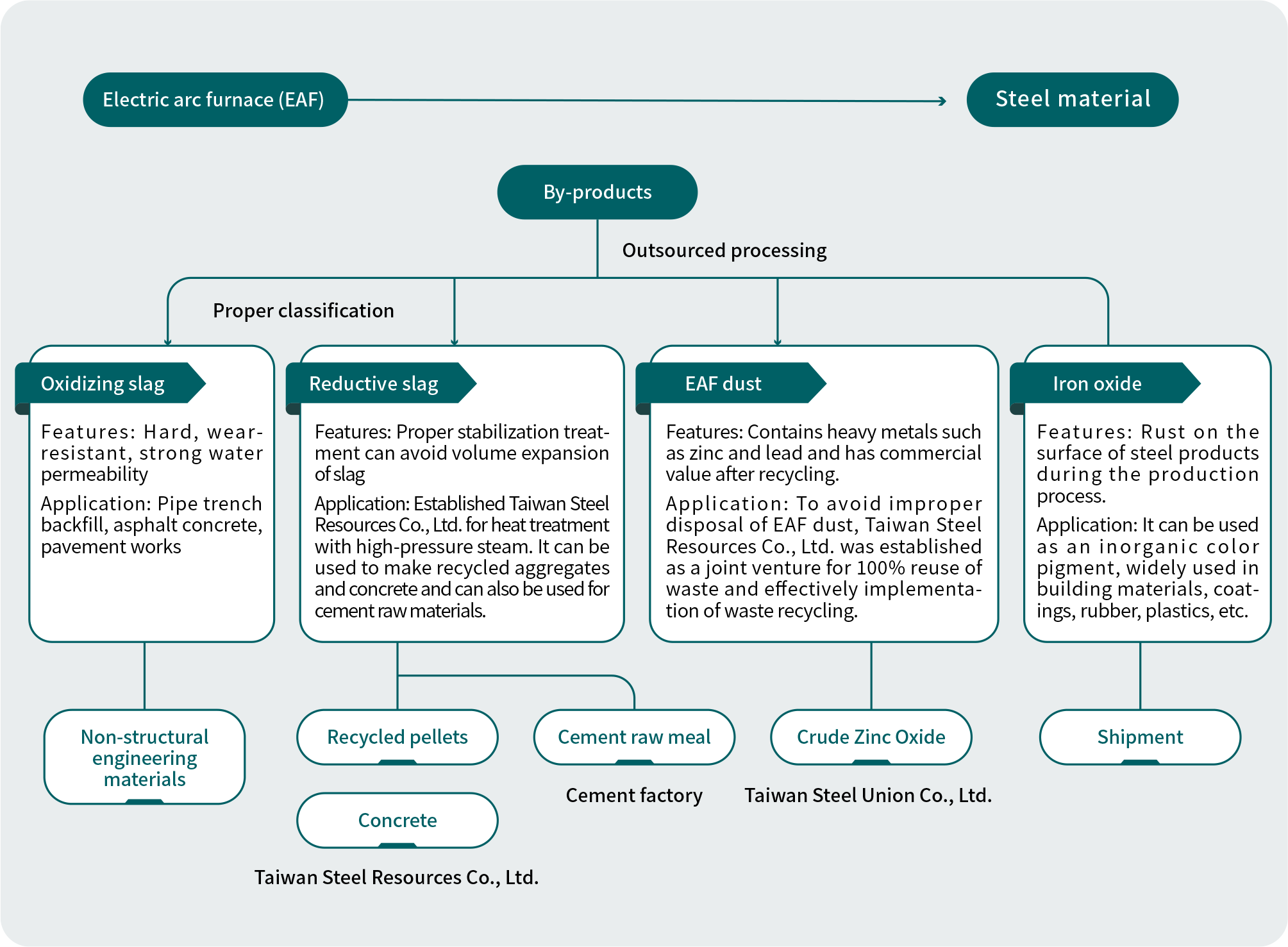

The major waste in Taoyuan Works and Miaoli Works are furnace slag and EAF dust whose amount of generation depends on the quality of the scrap steel, the main raw materials for steelmaking. Currently, the EAF dust generated is handed over to Taiwan Steel Union Co. to extract crude zinc oxide to be used as industrial raw material. The recycling and reuse of oxidizing slag is handed over to the recycling agency approved by the environmental protection agency, and after the oxidizing slag is crashed, magnetically separated and screened, it is used for non-structural engineering purposes. The recovery and reuse of reduced ballast is mainly handed over to the cement factory approved by the environmental protection agency to make cement raw meal, and part of it is sent to Taiwan Steel Resources Co., Ltd. for stabilization, which is used for non-structural engineering purposes. The total weight of waste amounted to 331, 241.3 metric tons in 2024, among which 331,092.8 metric tons were disposed and transferred (reuse or other recovery operations) and 148.6 metric tons were directly disposed (incineration), and the total waste recycling ratio (recycling and reuse) was 98.5%.

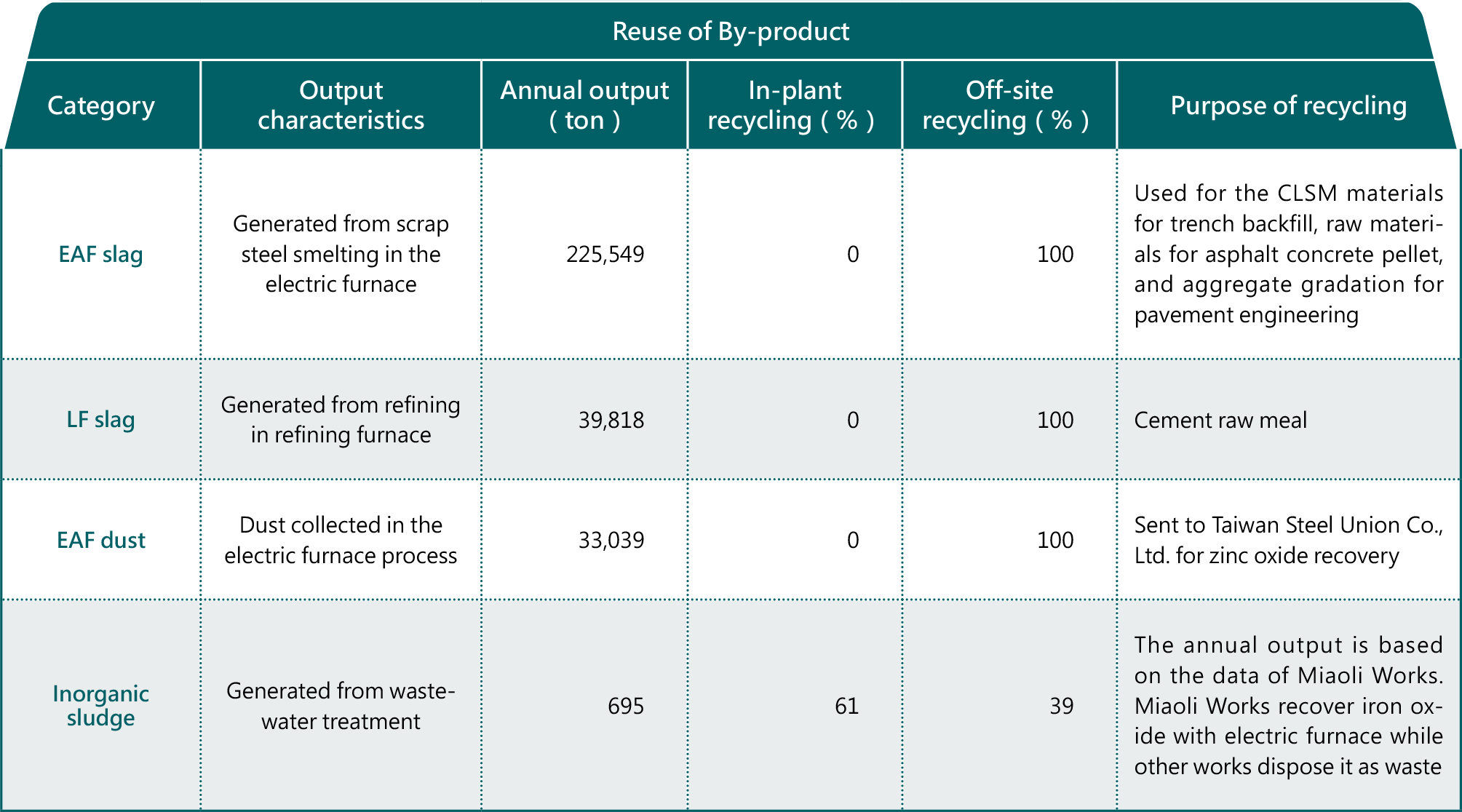

Reuse of By-product

Waste in all facilities is all recycled. The reuse method of oxidizing slag focuses on asphalt pavement, the base layer for subgrade, and CLSM. Tung Ho Steel commissioned National Taipei University of Technology to conduct research on the Application of Oxidizing Slag and Water Sludge Cake to the Controlled-Low-Strength-Materials (CLSM) and significant results have achieved. There will be more extensive application of oxidizing slag in the future. Tung Ho Steel also worked with Hao Sheng Industrial Co., Ltd. and applied oxidizing slag to the road pavement and subgrade projects of the Taoyuan City Government, and the application of oxidizing slag to local government road projects can effectively remove the waste, and it also has positive assistance in the construction quality and service life of the roads. It is hoped that the development of applying oxidizing slag to ultra-high-strength concrete can be further advanced to turn waste into gold.

To facilitate the promotion of EAF slag use, it is planned that the construction specifications is to be revised and that Taiwan Steel & Iron Industries Association compiles technical manuals to have complete integration of oxidizing slag reuse technology in Taiwan to serve as reference for engineering units. The manual of applying oxidizing slag to asphalt concrete pavement and the trial use manual of applying EAF slag to the aggregate gradation subgrade have passed the review by the Industrial Development Bureau. The manual of applying EAF slag to CLSM has also been completed and promulgated for implementation.

As for the reuse of reducing slag, it is introduced in the manufacturing process of cement raw meal, and through the cooperation with companies of Ruentex Materials and Taiwan Cement Corporation, the purpose of total removal of reducing slag is achieved, and 100% of it is used as cement raw meal. In addition, we applied for the Technology Development Program of Ministry of Economic Affairs through our affiliated company, Katec R&D Corporation, combined with the in-depth exploration of the basic properties and stability of oxidating slag and reducing slag by the Graduate Institute of Department of Materials Science & Engineering, National Chung Hsing University. The research results won the Outstanding R&D Consortium Award. Moreover, the reducing slag stabilization equipment of Taiwan Steel Resources Co., Ltd, has officially started operation, and the technology and development as well as the application manual will mature gradually. It is believed that it will make positive contribution to the complete recycling of the LF slag in Taiwan.