Environmental Protection

Use of Energy Resources

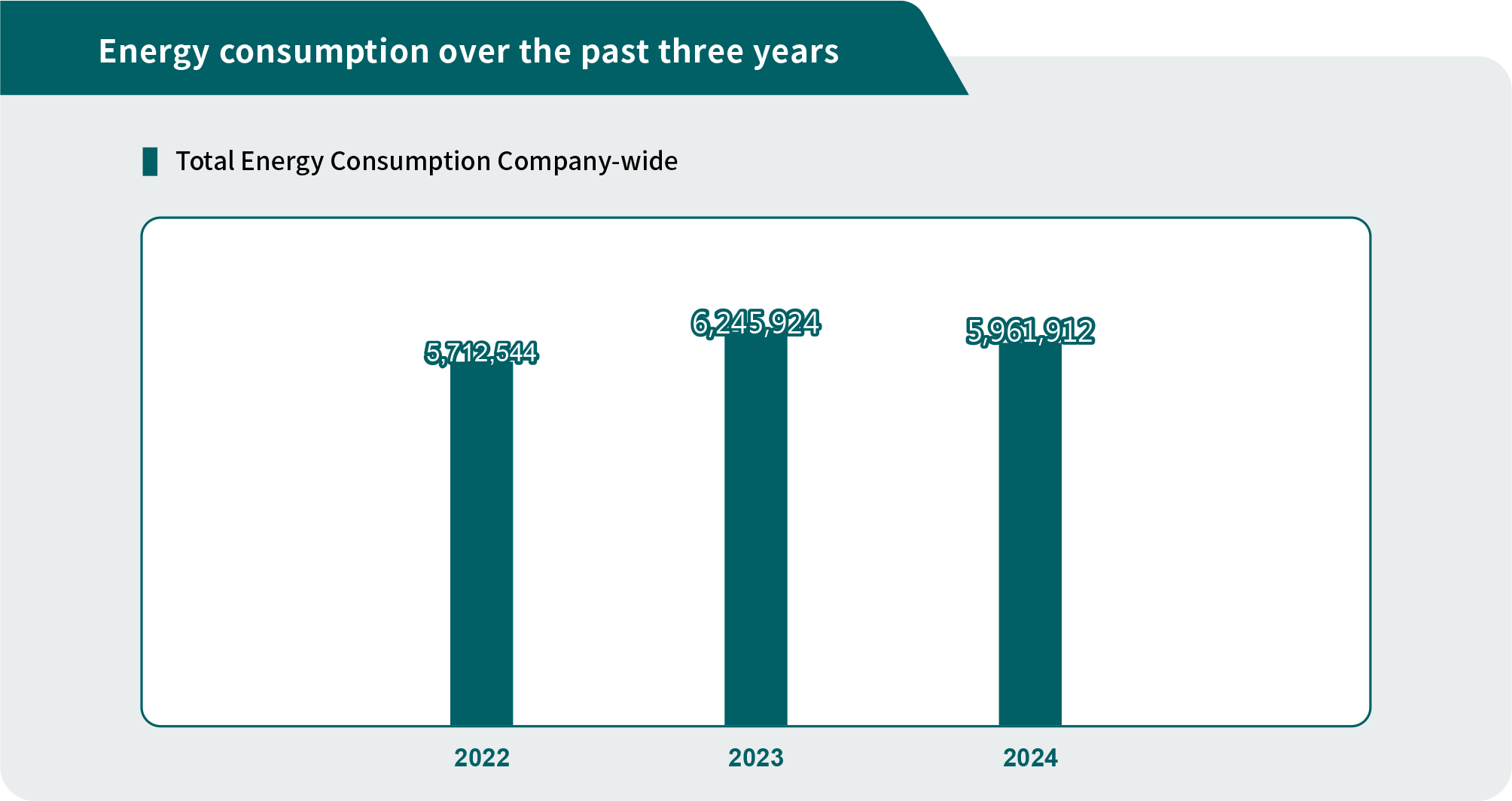

Tung Ho Steel has introduced ISO 50001 Energy Management System to continue monitoring the changes in energy usage at our works. The total energy use of the Headquarters and three Works in 2024 amounted to 5,961,912 GJ, including 4,139,621 GJ (1,149,328,563 kWh) from purchased electricity from Taipower, 131,435 GJ (36,509,776 kWh) from purchased renewable energy from Tung Kang Wind Power Corp., and 1,690,856 GJ non-renewable fuel (including 26,164 liters of gasoline, 947,361 kilograms of liquefied petroleum gas, 44,552,165 m3 of natural gas, and 1,952,133 liters of diesel). No renewable fuel was used, and the proportion of renewable energy use accounted for 2.2%note1.

1. Renewable energy usage ratio = Renewable energy purchased from Tung Kang Wind Power Corp. / Total energy consumption

2. Scope of energy calculation: In 2022, the scope included the Head Office, Taoyuan Works, Miaoli Works, and Kaohsiung Works–Jiaxing, and Kaohsiung Works–Daye was newly included in 2023 and 2024.

3. Energy use has been converted into GJ (1 GJ=109 joules)

Greenhouse Gas Inventory

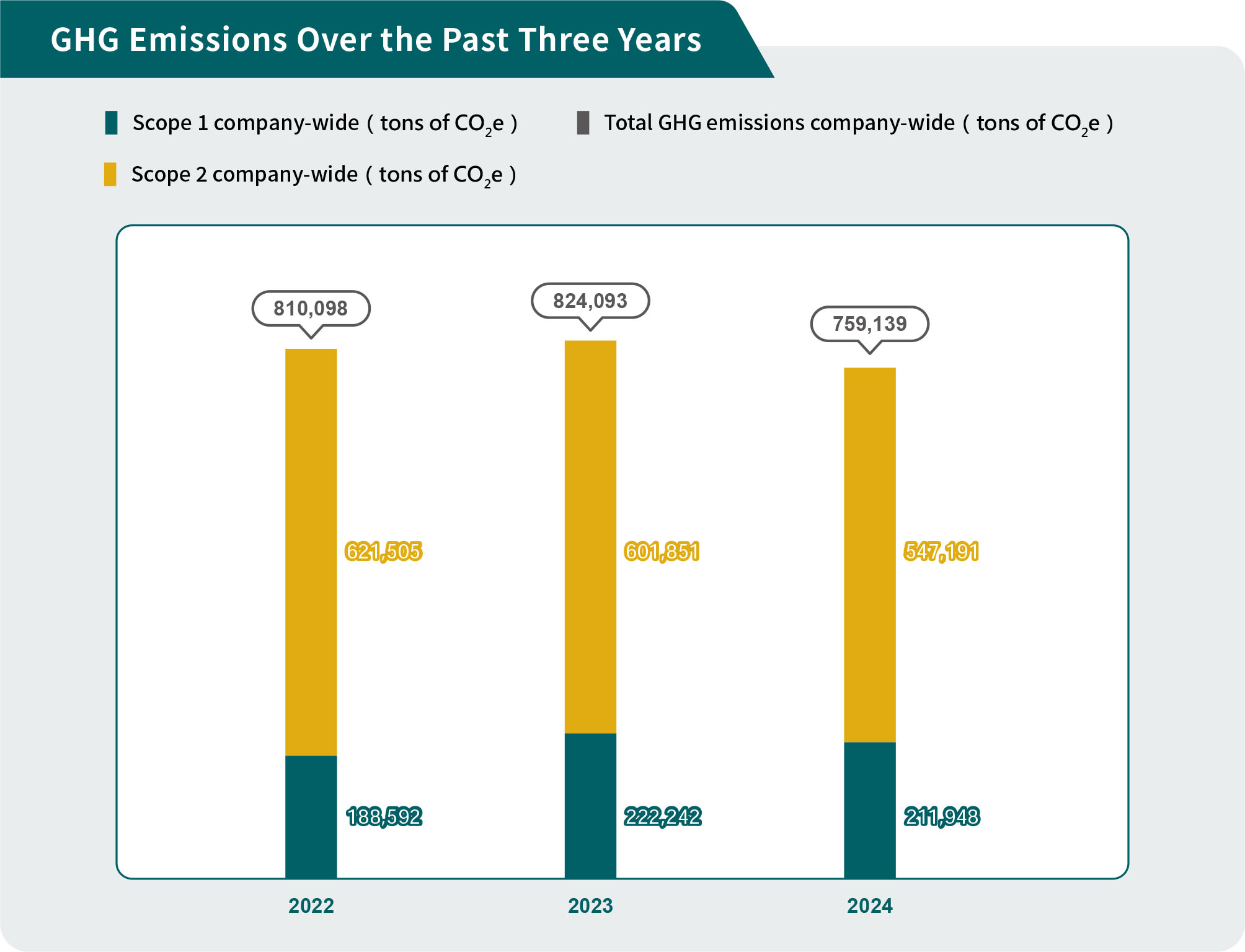

To cope with global warming and effectively mitigate the impact brought by climate change, Tung Ho Steel has been actively promoting energy conservation and carbon reduction. The ISO 14064-1 organizational GHG inventory system is introduced, and the GHG emissions are calculated by identifying emission sources, establishing activity intensity data, emission data, and setting up relevant management procedures for GHG emissions.

The GHG emissions of the Company can be divided into direct emissions (Scope 1) and indirect GHG emission from the use of purchased electricity (Scope 2). The inventory of Scope 3 conducted included upstream and downstream transportation and distribution, employee commuting, business travel, transportation of customers and visitors, fuel and energy related activities, waste generated in operations, downstream leased assets, and investments, covering items in Category 3 to 6 (Scope 3).

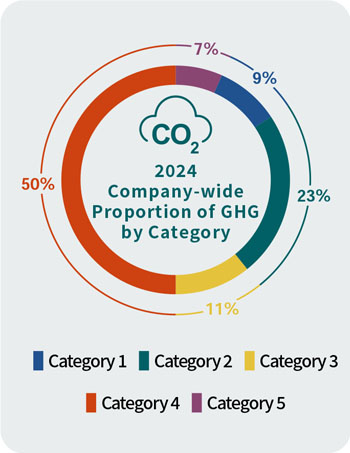

The Company’s 2024 GHG emissions included 211,948 mtCO2e from direct emissions (Scope 1/Category 1), 547,191 mtCO2e from indirect emissions from purchased electricity (Scope 2/Category 2), and 1,604,093 mtCO2e from Scope 3 (covering all items from Categories 3 to 6).

2024 Company-wide Proportion of GHG by Category

-

Unit: tons of CO2e Scope Category Description Emission Scope 1 Category 1 Direct GHG emissions 211,948 Scope 2 Category 2 Energy input 547,191 Scope 3 Category 3 Transportation 255,656 Category 4 Products purchased by the reporting company 1,170,589 Category 5 Use of sold products from the company 157,770 Category 6 Others - Total 2,343,153 -

1. The GHG inventory of our three works and the Head Office was conducted in accordance with ISO 14064-1 procedures and also passed the external verification by a third party. The method used to consolidate the amount of GHG emissions: operational control approach.

2. Scope of GHG inventory: In 2022, the scope included the Head Office, Taoyuan Works, Miaoli Works, and Kaohsiung Works, and Daye Works, Taoyuan Fabrication Center, Taichung Harbor Logistic Office, were newly added in 2023-2024.

3. Uncertain assessment of GHG emissions referred to the table of GHG emission coefficient management v. 6.0.4 released by Ministry of Environment and the Technical Specifications for Calibration and Inspection of Measuring Instrument.

4. Power coefficient was calculated with 0.474 kgCO2e / kWh in Scope 2 and that of Scope 3 was calculated using the Simapro database. The GWP used in the reports is the "IPCC Sixth Assessment Report (2021) version.

5. Types of greenhouse gases include carbon dioxide (CO2), methane (CH4), nitrous oxide (N2O), hydrofluorocarbons (HFCs), perfluorocarbons (PFCs), sulfur hexafluoride (SF6), nitrogen trifluoride (NF3) and so on.

6. Standards, methodology, assumptions and/or other calculation tools used: The energy consumption amount all came from estimates in the receipts or the monthly natural gas consumption statement and material sheet &AS400/ checklist of changes in material inventories by material part number, and there were no estimated values.

Water Resources

In the face of global warming and global climate change, Taiwan has experienced extreme climate in recent years, and the wet and dry periods are becoming more serious, leading to increased risk of water shortage. Therefore, we respond to the national water policy and reduce emissions, save water and increase the cooling water recycling rate. Our three works are located in Guanyin District in Taoyuan, Xihu Township in Miaoli County, and Kaohsiung Linhai Industrial Park. According to World Resources Institute’s (WRI) Aqueduct Water Risk Atlas, the water stress level of the regions our works are located in belong to “Low - Medium risk (1-2)”. The water resource of the Company’s business locations is mainly from tap water (sourced from reservoirs in different regions).

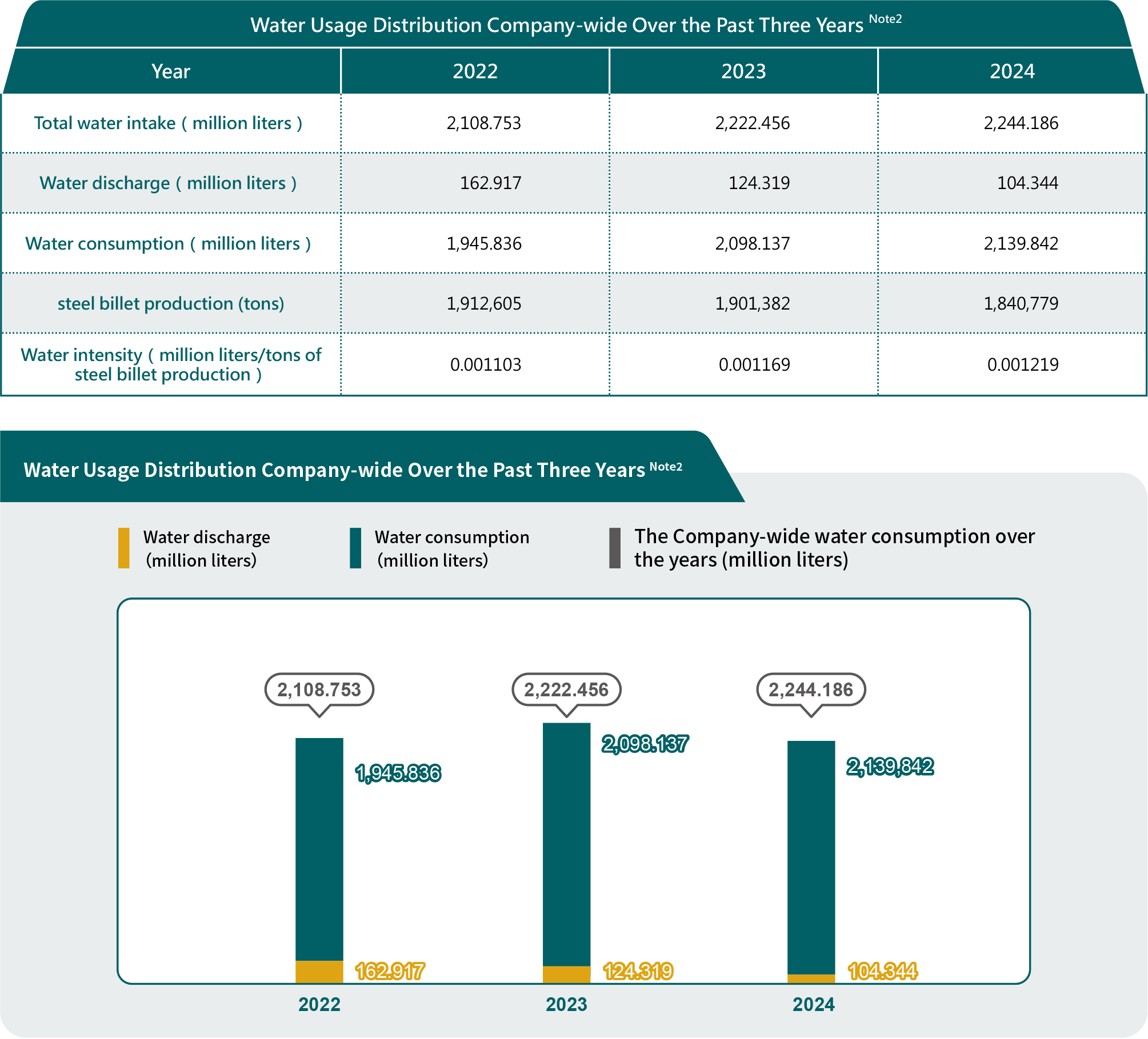

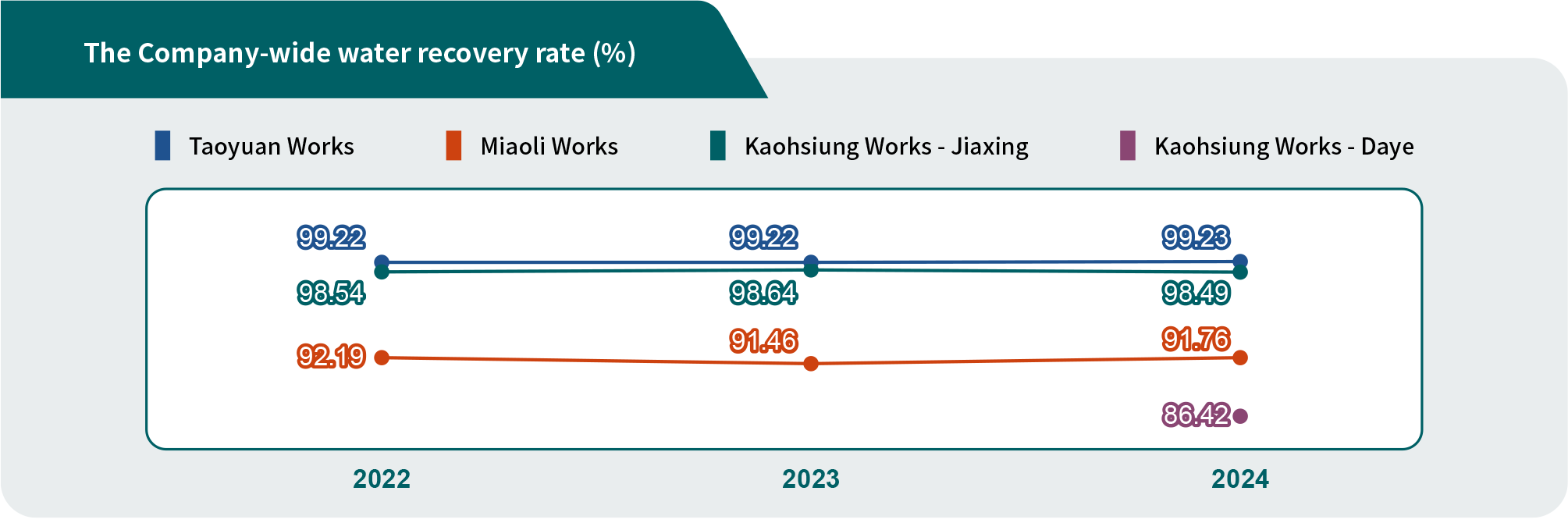

The main water uses for Tung Ho Steel are for cooling towers, process water, and domestic water. The water sources for each business base come from tap water (sources are reginal reservoirs: Shimen Reservoir, Liyutan Reservoir, Fengshan Reservoir, Feicui Reservoir), underground well water with water right, and rainwater collection. We have applied for the approved usage of tap water and underground well water from Taiwan Power Corporation and the local competent authority respectively. In 2024, the total water intake amounted to 2,244.186 million liters (tap water: 1,347.054 million liters, underground well water: 852.914 million liters, and rainwater: 44.218 million liters), and the water discharged amounted to 104.344million liters, with the total water consumption reaching 2,139.842 million liters. In addition, the process water is recycled and reused after sedimentation. Among them, water recovery rate of Taoyuan Works was even as high as 99.23%.

1. Water consumption = Water withdrawal (water usage) - Wastewater discharge.

2. Scope of water usage distribution calculation: In 2022, the scope included the Head Office, Taoyuan Works, Miaoli Works, and Kaohsiung Works-Jiaxing, while Kaohsiung Works-Daye Works was newly added in 2023-2024.

3. The tap water consumption was actual measured values and could be supported by water bills. Rainwater recovery of Taoyuan Works was an estimate value, and rainwater and underground well water of Miaoli Works were from the record of water meters.

4. Discharge volume is based on discharge water meter. The discharge volume of Miaoli Works, Kaohsiung Works-Jiaxing, and Kaohsiung Works-Daye Works include domestic sewage.

5. Unit conversion: One million liters is equivalent to one thousand cubic meters.

6. Total water withdrawal= Tap water intake + Rainwater harvesting + Groundwater (well water) extraction.

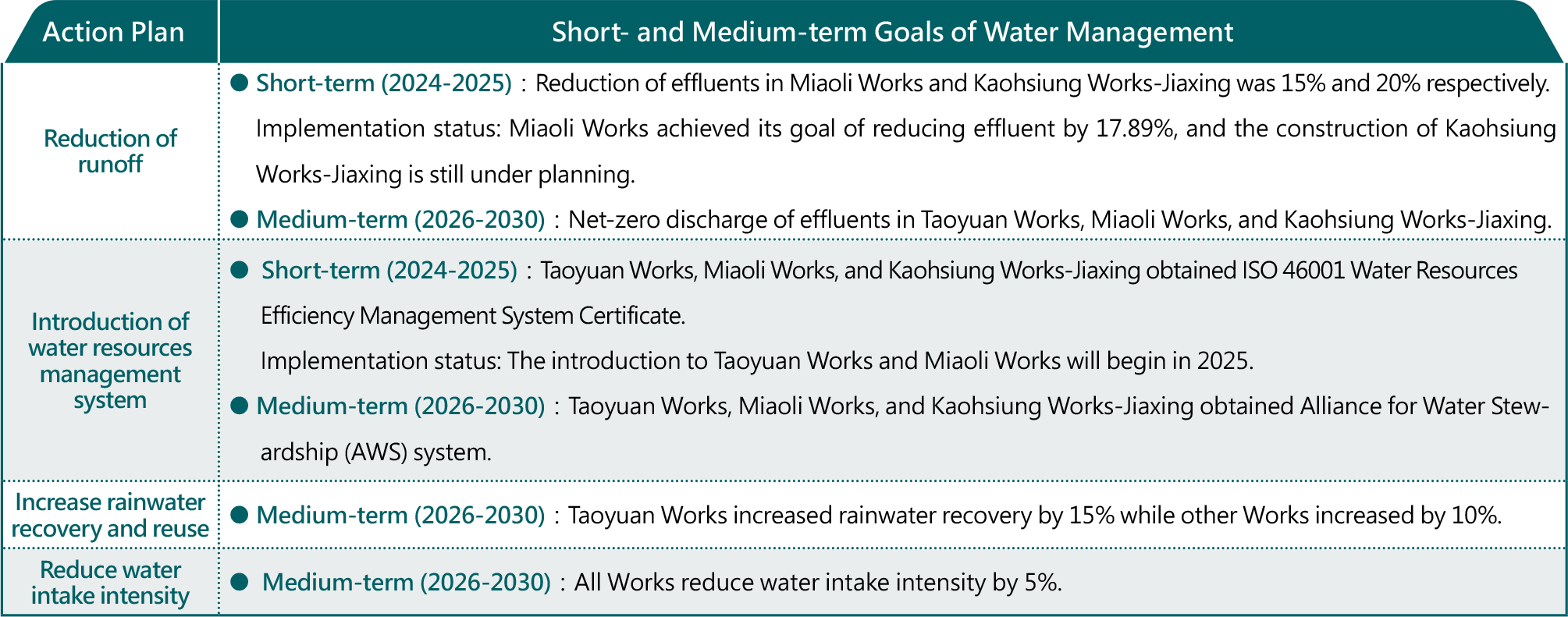

Water Management Strategies and Reduction Targets

The Company attaches great importance to water resources management and has set water management strategies and short- and medium-term reduction targets in 2024. Taking 2023 as the base year, the action plan includes reduction of discharged water, introduction of a water resource management system, increased rainwater recycling and reuse, and reduction in water withdrawal intensity, so as to lower the consumption and waste of water resources and reach sustainable use of water resources. The Company received a B-level rating in 2024 CDP Water Security Questionnaire, showing that it has entered the water resources management stage and taken integrated actions on water-related issues.